| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : Sinuo

Model Number : SN2501T-30V250A

Certification : Calibration Certificate (Cost Additional)

Place of Origin : China

MOQ : 1

Price : Customized

Payment Terms : L/C, , T/T, Western Union, MoneyGram

Supply Ability : 1 set per month

Delivery Time : 30 Days

Packaging Details : Plywood

Applied Standard : IEC 60898-1, IEC 61009-1

Tester Capacity : 45kVA, 15kVA per phase

Output Current : AC0-10A, 50A, 250A

Insulation Resistance : ≥ 5 megohms

Output Voltage : AC 5-40V

Timing Range : 0-999h

Transformer Ratio : 250/5A

Current Error : ±0.5%

IEC 60898-1 Circuit Breaker 28 Cycles Test Equipment 30V250A

Product information:

It complies with the requirements of IEC 60898-1, IEC 61009-1, and IEC 60947-2 standards, and can perform 28-day and night temperature rise current characteristic tests on small circuit breakers (1-125A).

The test bench is a set of three. That is, three power supplies are installed in one cabinet, and each can be operated independently of each other. Three power supplies can also be used at the same time, and the phase angle difference of the three output currents is 120 degrees.

At the same time, three products are tested in series, with a 21h power-on + 3h power-off timing function in the 28-day test of MCB products. The open-circuit voltage of the test power supply is not less than 30V, and an inductor is used as a load. During the test, heat is reduced and electricity is saved.

Main configuration description:

The main control system consists of: 15-inch MCGS touch screen, Omron PLC, automatic compensation AC, and corresponding host computer software program, automatic control.

Electronic constant current source:

The constant current source independently developed and produced by our company is adopted. It is composed of Infineon IGBT parallel connection, Swiss CONCEPT driver, ADSO film capacitor parallel connection, high-power common mode inductor parallel connection, high-speed computing processor, high-precision mutual inductor and other components. Voltage, current and temperature detection are designed on the primary and secondary sides. Regardless of any abnormal situation (voltage is too low, voltage is too high, current overshoot, current fluctuation, temperature is too high, etc.) at the front or back end of the power supply, the software will automatically adjust and protect it. At the same time, the power supply itself will stop working, and the secondary protection will be carried out from the hardware, which is faster and ensures that the IGBT module is not damaged.

Special current booster:

It adopts R-type winding of all-copper coil, and 2 windings are connected in parallel, which can well reduce its own magnetic leakage. And it adopts imported high-performance silicon steel sheets, and 100% utilizes the circular section. Therefore, the current booster has a small no-load current, low noise, sufficient and stable output power.

Inductive load:

The test voltage is greater than 30V, and the long-term power-on test will consume a lot of electricity and a lot of heat. Therefore, using air-core inductors as loads can solve the above problems. In order to match the test currents of different products, 6 groups of inductors are used in series and parallel combinations through contactors for automatic switching.

Parameters:

1) Voltage: AC 380 (1±10%) V.

2) Frequency: 50HZ±1HZ.

3) Test bench capacity: 45kVA, 15KVA per phase.

4) Output Voltage: AC 5-40V (the open circuit voltage of the circuit is at least 30V)

5) Output Current: AC 0—10A, 50A, 250A, continuously adjustable in steps, 3 current outputs in independent steps, direct display of current effective value.

6) Timing Range: 0-999h, minimum resolution 1S.

7) Current Transformer Ratio: 250/5A, accuracy level: 0.2.

8) Equipment Insulation Resistance ≥ 5 megohms.

9) Current Error ±0.5%.

10) The control display screen adopts a 15-inch MCGS touch screen.

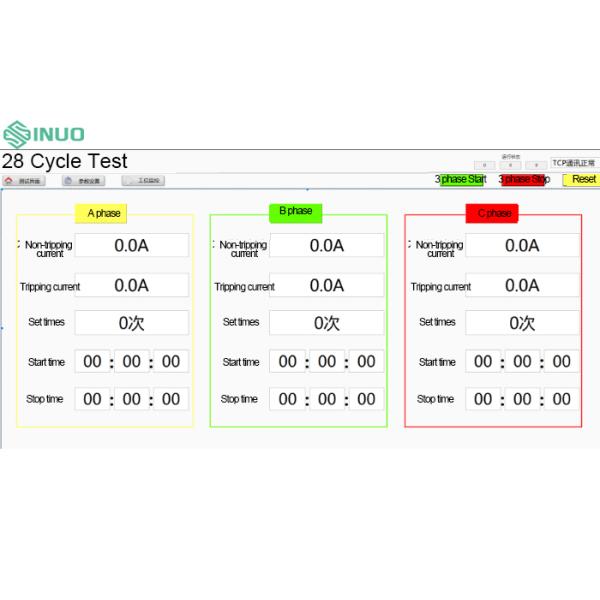

Test screen:

|

|

IEC 60898-1 Circuit Breaker 28 Cycles Test Equipment 30V250A Images |